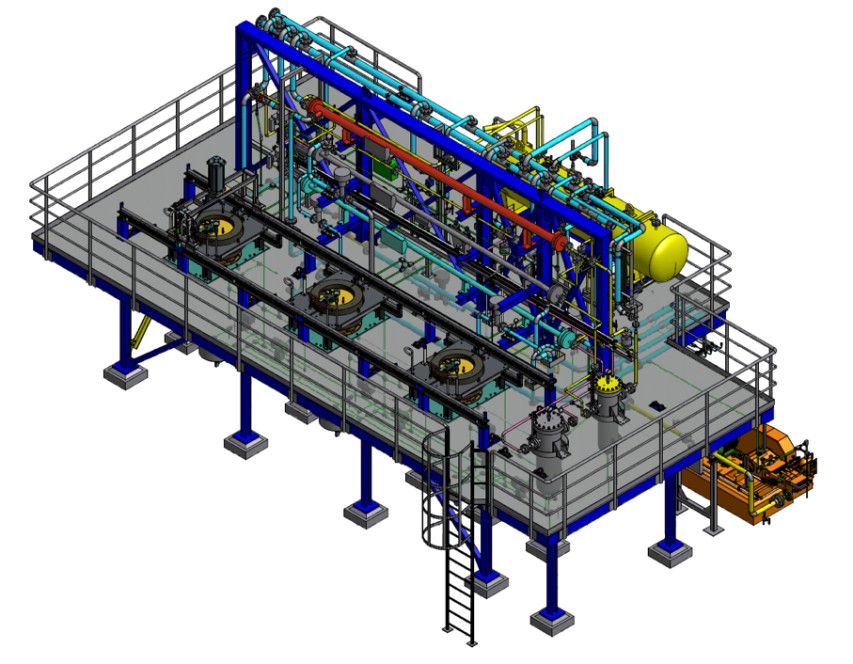

Pilot Plant Skid Unit

Pilot Plant Skid Unit Manufacturers

The multifaceted design and scope of the many design companies are intricate enough. don’t work with a design accomplice who will further confuse the strategy. The asp industrial solution offers the full scope of designing administrations in-house. recommending that you generally discuss with the source so that nothing is confused in the interpretation.

Our clients trust us to tackle their toughest exam challenges. We have planned frameworks that include all the activities of the unit and that in fact. we move forward with disciplines that are being developed as of now. Our unrivaled depth of specialized information makes us the right partner. to help you overcome any barrier between plate sets and business.

Pilot Plant Skid Unit Suppliers

asp plans and builds skid-mounted industrial solutions, pilot programs that show levels of large-scale creation through placed instrumentation and test stations. Unlike other pilot plant slide manufacturers, our master design group can help you plan your modules and ensure quality build and collection, all under one roof. We offer a master plan, mechanical, and framework. Pilot Plant Skid Unit Manufacturers.

A pilot plant can be a pre-company creation framework that uses start-up innovation and also offers small volumes of the latest innovation-based items, to find out about the new innovation.

The information obtained is used to plan large-scale creation frameworks and commercial elements, as well as recognizable evidence of more exploration targets and support for speculation options. Other (non-specialized) purposes include acquiring public aid for pristine advancements and addressing government regulations. Pilot Plant Skid Unit Manufacturers.

The plant could be a relative term in the sense that pilot plants are more modest than large-scale creation plants, but are built in a variety of sizes. Also, as pilot plants are expected to learn, they are more adaptable, to the detriment of the economy.

Some pilot plants are embedded research centers using stock laboratory equipment. while others need generous design efforts, cost many dollars, and are collected and created from measurement hardware, instrumentation. and pipeline. they will even be used to preparing labor for a large-scale plant. In general, the pilot plants will be more modest compared to the display plants.

Programmatic experiences and semi-exact strategies often decide the limitations of the pilot-scale framework. These numerical models are then tested during a real pilot plant. Pilot Plant Skid Unit Manufacturers Different visualization strategies are used to magnify. These techniques include:

Numerical proof

Aspen Plus / Aspen HYSYS demonstrating

Limited Elemental Analysis (FEA)

Hydrocracking pilot plant

Computational Fluid Dynamics (CFD)

These hypothetical demonstration techniques return the following:

Mass and energy adjustments completed

Limit and advanced frame plan

Hardware needs

Frame impediments

The reason for deciding the value of conducting the pilot module.

Pilot Plant Skid Unit in Vadodara

They are less expensive to manufacture than large-scale plants. The company does not jeopardize the greatest amount of capital in a task that will be useless or impossible. Also, plan changes are made more on a pilot scale and wrinkles within the interaction are fixed before the monster plant is made.

They provide important information for planning the large-scale plant. Logical information about responses, material properties, destructiveness, for example, could also be accessible, but it is difficult to foresee the development of a course of any complexity.

Design information from other interactions could also be accessible, but this information generally cannot be applied to the technique out of interest. The designers use the information from the pilot plant to refine their collection scale office plan.

In the event that a framework is well defined and so the design limits are known, no pilot plants are used. For example, a company that wants to expand the creation limit by building a replacement plant. that does something comparable to a current plant might not use a pilot plant.

Pilot Plant Skid Unit in Gujarat

Furthermore, replication of propellants in measure on PC has broadened the presumption of cycle makers and decreased the need for pilot plants. In any case, they are actually used as even best-in-class reproduction cannot expect the making of intricate frames. Pilot Plant Skid Unit in Gujarat,

As a frame expands in size, the properties of the frame that depend on the amount of problem (with broad properties) may change. The region-to-fluid ratio during a production line could be a model of such property. On a small synthetic scale, during a flask, say, there is a huge region to fluid ratio. Pilot Plant Skid Unit in Gujarat,

Be that as it may, if the referenced response increases to accommodate over a 500-gallon tank, the region to liquid ratio turns out to be much more modest.

Pilot Plant Skid Unit in Vadodara As a consequence of this distinction in the region-to-fluid ratio, the exact idea of thermodynamics and the response energy of the technique change during a non-direct design. This is why a response during a measuring cup can act in a unique and unlimited way in contrast to an identical response during a huge-range creation measurement.

Different variables

The different variables that will change during the change to a building scale include:

3D model of a multi-motif pilot plant

Response energy

Substance balance

Material properties

Liquid elements

Thermodynamics

Team choice

Disturbance

Consistency / homogeneity

Once the information on the activity of a pilot plant has been collected, a larger scale creation office could also be built. Pilot Plant Skid Unit in Vadodara

But, a sign plant, which is generally larger than a pilot plant, although more modest than a full-scale creation plant, could also be worked on to show the commercial viability of the strategy. Organizations, from time to time, continue to work in the pilot plant to actually search for new plastic items, new raw materials, or various working conditions. But, they will work as creation offices, expanding the creation from most of the plant.

Contrasts between seat scale, pilot scale, and presentation scale are affected by industry and application. Some companies use the pilot plant and the show plant in reverse. Some pilot plants function as convenient modules that will ship as a contained unit. Pilot Plant Skid Unit Suppliers

For group measurements, within the drug business, for example, the seat scale is generally carried out with examples of 1 to 20 kg or less, while pilot-scale tests are carried out with tests of 20 to 100 kg. Show scale is actually working the equipment at full commercial feed rates over extended periods of time to prove functional robustness. Pilot Plant Skid Unit Suppliers.

In the improvement of the most recent cycles, the organization and activity of the pilot. and exhibition plant will be executed in correspondence. with the organization of the commercial plant in the longer term, and the results of the pilot test programs are fundamental to improve the flow chart of the commercial plant. .

It is normal in situations where the measure innovation has been executed that the enterprise-scale reserve funds that are generated due to the pilot tests will offset the value of the pilot plant itself.

About US

ASP Industrial Solution is an Engineering Consultancy based at Vadodara, Gujarat in India catering Engineering Services to various Industries like Chemical, Allied Chemical, Agro Chemical, Petrochemicals, Oil & gas, Bulk Drugs, Pharmaceutical and Speciality Chemicals etc.

Registered/Work address

SF/12, Petal Trillium Before Navrachna University @ 24 MTR, High Tension Rd, Bhayli, Vadodara, Gujarat 391410, India.

E-mail:

info@aspindustrialsolution.com,

aspind.solution@gmail.com